What are Bugholes in Concrete and Why Do They Form?

Concrete’s strength, durability, workability, and versatility make it the material of choice for projects that have to last and look good. But despite its popularity for high-profile applications, achieving a perfectly smooth finish can be very difficult.

By Aaron Ausen | March 12, 2025

The Ground Work

Short on time? Here are this article’s key takeaways…

Bugholes are small surface cavities caused by trapped air during the curing process of concrete.

Factors like excessive vibration, too much form release agent, inconsistent mix composition, and poor form design can increase the occurrence of bugholes.

While air pockets cause bugholes, air entrainment is also necessary for concrete durability, making their complete elimination impractical.

Proper quality control, mix adjustments, and form maintenance help reduce bugholes and improve concrete surface quality.

Why Do Bugholes Form?

It bears to mention that air is a naturally occurring aspect of concrete production, and it’s nearly impossible to eliminate all air from the process. Several occurrences during production can, however, increase the presence of bugholes.

Excessive Vibration

Segregation occurs when the paste of a concrete mix separates from the aggregate, resulting in air pockets and weaknesses. The typical cause of segregation is excessive consolidation (vibration) in the concrete production process. Concrete can be consolidated internally – by inserting a vibrating tool directly into the mix – or externally with an apparatus attached to the form.

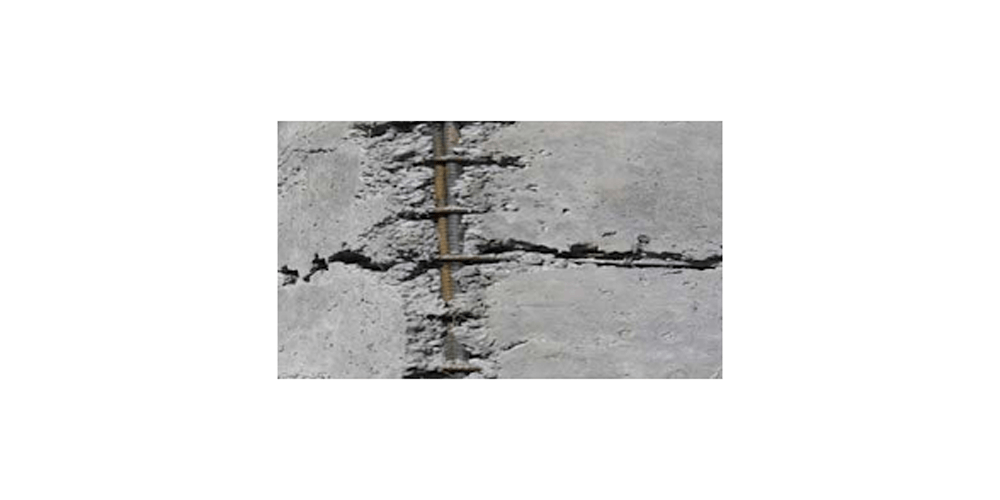

Underconsolidated concrete can also result in bungholes or, worse, structural issues. It can appear as minor bungholes or as extreme as exposing aggregate and steel, which may threaten the overall structural integrity of the product.

Excessive Form Agents

Release agents are often applied to forming systems to make it easier to remove the finished product without damaging its surface or the form itself. Using too much of an agent can have the opposite effect on the product’s surface, forming bugholes. Bug holes created this way are often smaller, more highly concentrated, and can be referred to as pinholes.

Inconsistent Mix Composition

Improper mix design can also lead to bug holes. The most common mix issue is a change in moisture content, which can drastically affect the fluidity of the concrete and, ultimately, the finished product’s appearance. Appropriate quality control programs and recipe component monitoring can minimize mix design issues.

Poor Form Design or Preparation

Properly cleaned and sealed forms are key to producing a consistent and attractive concrete product. If a form has mix build-up or leaks concrete paste, segregation can occur, and air can be introduced into the product. This can often be confused with bug holes, but the defining characteristic is imperfections near edges or form openings.

The presence of air in concrete is a naturally occurring process, and entrained air adds durability to concrete. Concrete can be formed to produce durable, attractive, and versatile solutions, but addressing its imperfections can be challenging due to the many variables in play. Diligence and attentiveness in manufacturing processes can reduce the causes of bugholes and deliver more attractive finished products and projects.

Contributing Expert

Aaron Ausen

Aaron was practically born into the concrete industry. He spent more than 20 years with his family's Janesville, Wisconsin, precast business before joining Rosetta Hardscapes in 2018 in manufacturing specialist and business development roles. As sales director, Aaron now leads Rosetta's global production network expansion and manufacturer support efforts. Outside of work, Aaron loves to coach youth sports and spend time on his hobby farm.